With a relationship stretching back over 20 years, Universal Hydraulik shares our family-run ethos and strong commitment to customer support. Our businesses have developed and evolved closely ever since and we are proud to be the only supplier of Universal Hydraulik components to the UK market.

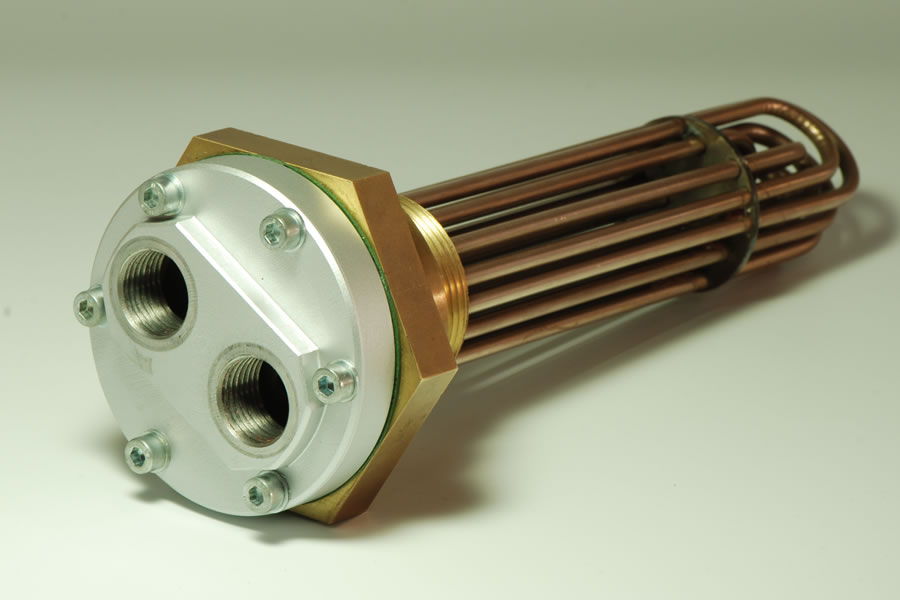

Universal Hydraulik offers products for a wide range of applications, and is a leading European hydraulics manufacturer of power units. They also specialise in the design and production of heat exchangers, which are available as air / oil and oil / water and specialist units.

Hydraulic Alliance has successfully designed these units into major operational oilfields and research/exploration missions and vessels: applications which demand the most stringent safety and environmental standards. We have also supplied solutions for:

- Marine, Offshore

- Military

- Compressors

- Automotive

- Gearbox and offline cooling and filtration

Safety Heat Exchangers

Being the first manufacturer to incorporate the monitoring of fluid and pressure differential on both mediums into its hybrid units, the failsafe heat exchanger can be used in both new and older applications. The level of instrumentation and degree of interaction can be tailored to the customers’ needs and demands. This could be from a simple signal to CAN-Bus or HART Protocol linking the entire system.

In a world where environmental impact is an ever more critical performance requirement, the failsafe unit design helps eliminate system fluid contamination of water sources. It equally serves to protect water contamination of your system fluids; potentially reducing maintenance and extending the life of your system.

Atex Heat Exchanger

The standard range of units – both shell and tube and air blast – can be supplied with ATEX classification. Each unit is produced to order and is designed from a customer ATEX questionnaire to meet your individual system needs. Built in the European Union, the quality of manufacturing materials is guaranteed to meet the highest standards.

PIGGYBACK Compressor Oil & AIR Coolers

A recent innovation for a leading German compressor manufacturer, this solution helps to deliver space and cost efficiencies. With the increase in the size of modern primary movers to meet ever more stringent emissions legislation, piggyback coolers can help maintain overall system envelope size by replacing two components with one. It also utilises the water or cooling supply into one piece to perform two functions.

Whether inline or offline, heating, cooling or precision control of a medium, we are able to design and supply the right solution.